Keep track of all your equipment, in real time, all the time.

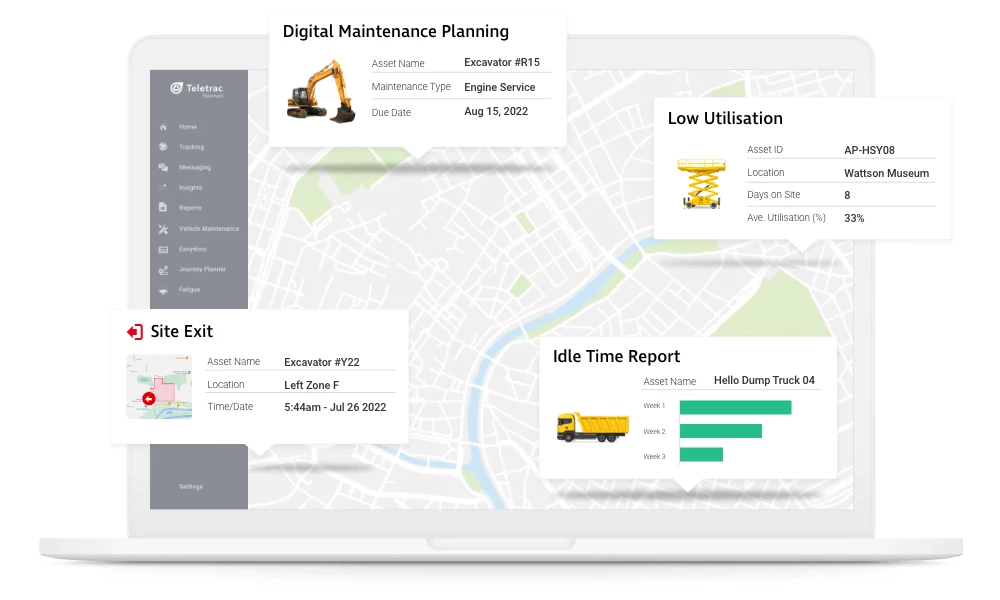

Improve how you manage equipment with full visibility into its location, use and maintenance. Know how and when each jobsite is using your powered and non-powered assets and avoid problems with accurate, real-time information. With visibility into unused assets you can prevent equipment hoarding and reallocate assets where they’re most needed. Digital processes can ensure high asset utilisation and reduced costs.

Build Your Solution Explore the Platform

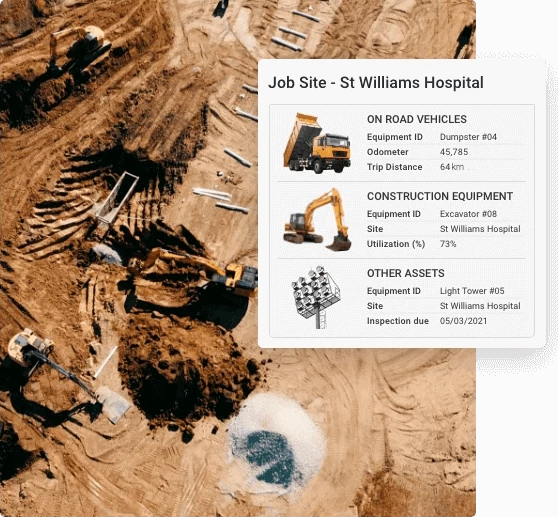

With a range of powered and non-powered assets across job sites, it can be a challenge to keep track of location, costs, maintenance schedules, and other factors that affect your bottom line. GPS tracking, along with insights into maintenance alerts and fuel usage, combines to give you a detailed picture of your operations. Discover instances of equipment hoarding to keep your assets in use. Identify opportunities to reduce costs and increase efficiency.

Reduce equipment downtime with digital maintenance plans that run off engine hours data. Get automated alerts when scheduled maintenance is due and quickly responded to unplanned maintenance needs with real-time diagnostic alerts and our digital inspection app. The fully integrated inspection app enables you to digitise your entire maintenance process from identification to completion, giving you complete visibility and confidence that your equipment is ready for use.

By monitoring equipment assignment and usage across your job sites, you can maximise utilisation and accomplish more with less. You will have clear data that enables you to manage your assets with confidence and transparency, helping you and your job site managers complete projects on time.

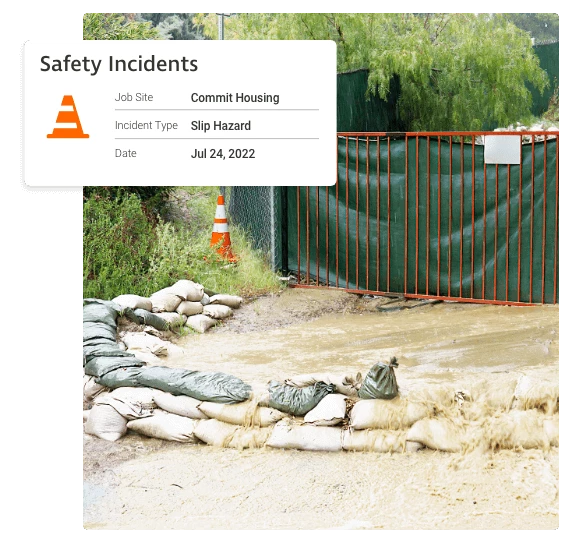

Whoever is using your equipment, and wherever they’re using it, it’s important to know they’re complying with all relevant regulations. Equipment monitoring tools provide insights into operator behaviour, and geofencing lets you keep the equipment where it belongs. Take advantage of real-time diagnostics and alerts to prevent potential violations.

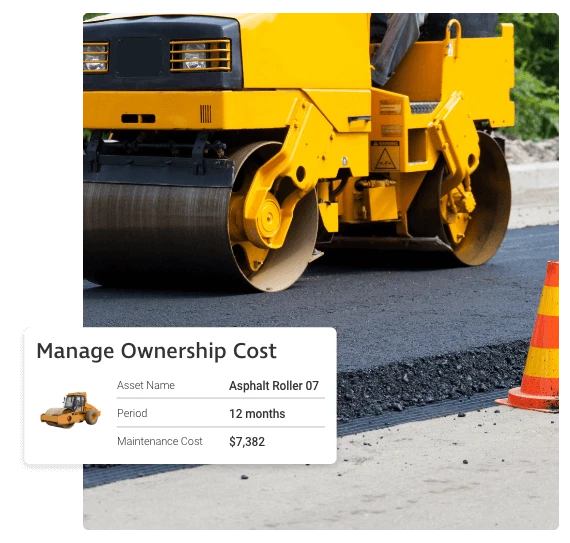

Keeping track of your equipment allows you to produce reports that help you make educated decisions. You can see the cost of ownership for each piece of equipment and which ones are breaking down most often. You can also track rental costs to help decide when to rent versus buy and know when a new piece of equipment will pay for itself.

Get a clear picture of your equipment ownership costs with tracking software and discover opportunities to save money.

$15.5 billion

$15.5 billion

global construction industry growth by 2030

39%

39%

Companies using telematics who saw improved driver efficiency

30+ years

30+ years

Teletrac Navman’s equipment management experience

Equipment tracking and asset management systems give managers the information they need to minimise equipment hoarding as the software measures machine work versus idle time, helping management identify underutilised assets. You can also establish “internal rental rates” to financially incentivise employees to return equipment promptly.

A computerised maintenance management system (CMMS) allows you to automate monitoring and scheduling vehicle maintenance. Using a CMMS can make scheduling of maintenance more efficient and reduce administrative labor. The system can monitor maintenance intervals for an entire fleet and provide automatic reminders when scheduled maintenance is due. This proactive approach can prevent equipment failure and unexpected, expensive repairs.

A digital maintenance log is the key to tracking inspections. It puts the reports—along with the entire history of each piece of equipment, engine hours, current location and upcoming service needs—online. You can access them from anywhere in real time. No more flipping through books and manually entering data into spreadsheets. Instead you will always know when inspections are due and when they’ve been completed.